Model EGLF-12A is a fully automatic stick hot filling cooling production line designed for the production of petroleum jelly, deodorant stick, sunscreen stick, and other multi-stick tube filling, capping, and labeling.

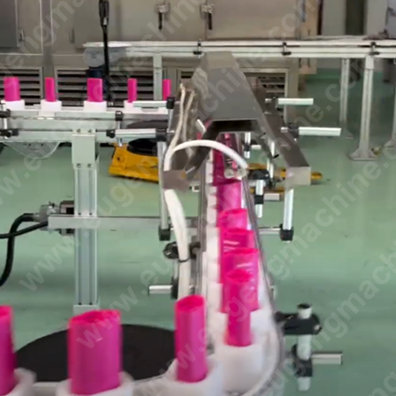

Working process: 1200L heating mixing tank automatic feeding connection to filling tank, Automatic loading bottles into pucks on conveyor by push system, 12 nozzles filling machine, 10P Cooling tunnel to cool whole hot liquid being solid product, Re-heating for surface flat again for top filling products, Re-cooling for top filling products surface fast shrink, automatic feeding cap by vibrator, High speed cap press machine, Hold conveyor separate the finished products from pucks, Front and back with round wrap labeling 2 in 1 labeling machine, Laser coding machine as option.

1.Target Products

|

|

|

|

2.Descriptions

3.Specifications and Parameters

| Model No. | EGLF-12A |

| Output capacity | 80-100pcs/ min |

| Filling volume | 0-250ml |

| Filling type | Piston filling system, driving by servo motor |

| No. of nozzle | 12 |

| No. of operator | 2 |

| Display | PLC |

| Tank volume | 1200L melting tank+50L/set jacket heating mixing tank |

| Powder consumption | 40kw |

| Air put | 4-6kgf |

| Dimension(M) | 16×6×2.2 |

| Weight | 7500kgs |

4.Details

|

|

|

|

| 1200L storage tank, auto pump | Automatic loading empty tube into puck | Removable 50L heating mixing tank | 2 sets of 6 nozzles filling machines |

|

|

|

|

| Cooling tunnel, 5m*1.86m*2.2m | 11 line loops conveyor design | Refrigerant R404A, R448A, R449A,R452A | Re-heating for surface flat again |

|

|

|

|

| Re-cooling for top fill surface fast shrink | Automatic loading and capping machine | 2 sides with round wrap labeling machine | Laser coding machine |

5.Reference Video