Hot selling nail polish filling machine

Introduction

With the beauty economy thriving, nail varnish is one of the must-have buzzing consumer goods in the world. The need for basic machines is resorting to hygienic solutions products due to the increase of its high quality, carved content used in nail polish reliability and customer demand. Switching to this automatic nail polish filling machine–This machine comes up with automation, efficiency, and an integrated production line. So you can imagine how efficient the cosmetics industry will become after using it. Learn about the features of a nail polish filling machines and how they revamp your integral part?

What is Nail Polish Filling Machines Are Hard to Get

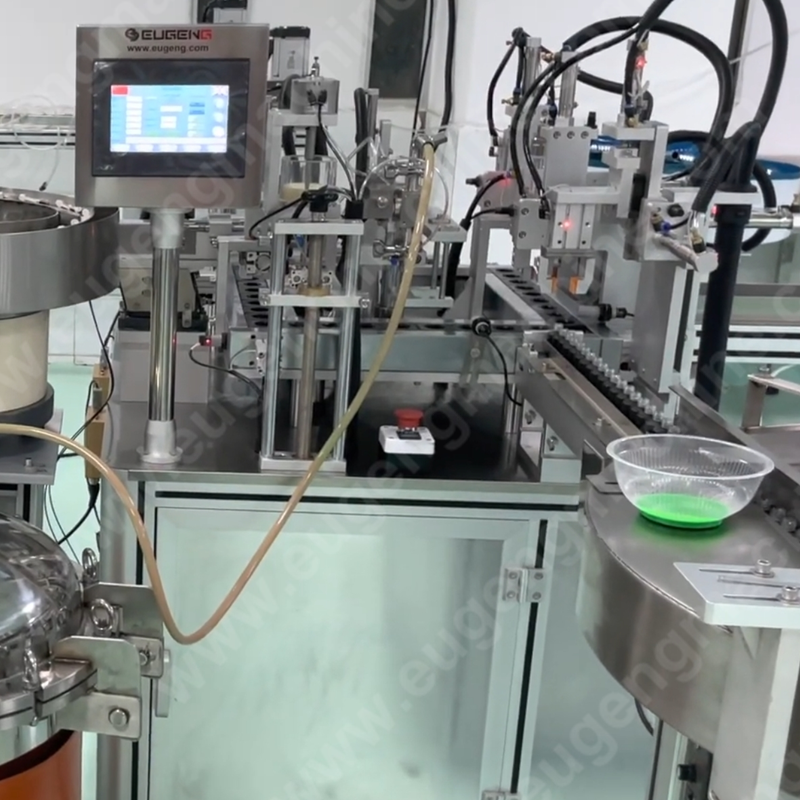

The machines filling nail polish are designed for the purpose of filling nail poLish containers wiTh Long Lasting, consistency and uniformity. Such machines operate on different principles (i.e. piston pumps, peristaltic pumps) also considering the viscosity of nail polish composition. The production requirement varies, and machines are manufactured in different forms such as the manual and fully automatic.

Important Features of Nail Polish Filling Machines

Nail Polish Filling MachineWell, some of the significant features found in nail polish filling machines are:accuracy and precision in dispensing speed and efficacy easy to changeover for different bottle sizes likewise, as nail polish is directly related with the consumer so hygiene and sanitation standards are also significant.

Benefits of Nail Polish Filling Machine

The nail polish filling machine has many benefits. It enables manufacturers to meet the increased demand for nail polish while preserving the product integrity during filling More often than not, inline formulation of such products can have several problems that includeGains in Production EfficiencyQuality and ConsistencyLabor and Human ErrorLossSustainability & Waste Disposal It allows manufacturers to keep up with the massive requirement for nail polish whilst keeping the product intact through the filling process.

Data to Read specificationtechnical

Filling accuracy and repeatability, output rates, capacity, machine dimensions and footprint as well as compatibility with the nail polish production line are some of the important factor which governs selection of nail polish filling machine. These qualities will ensure the machines you select meet the specific needs of your production facility.

Integrating with Other Production Systems

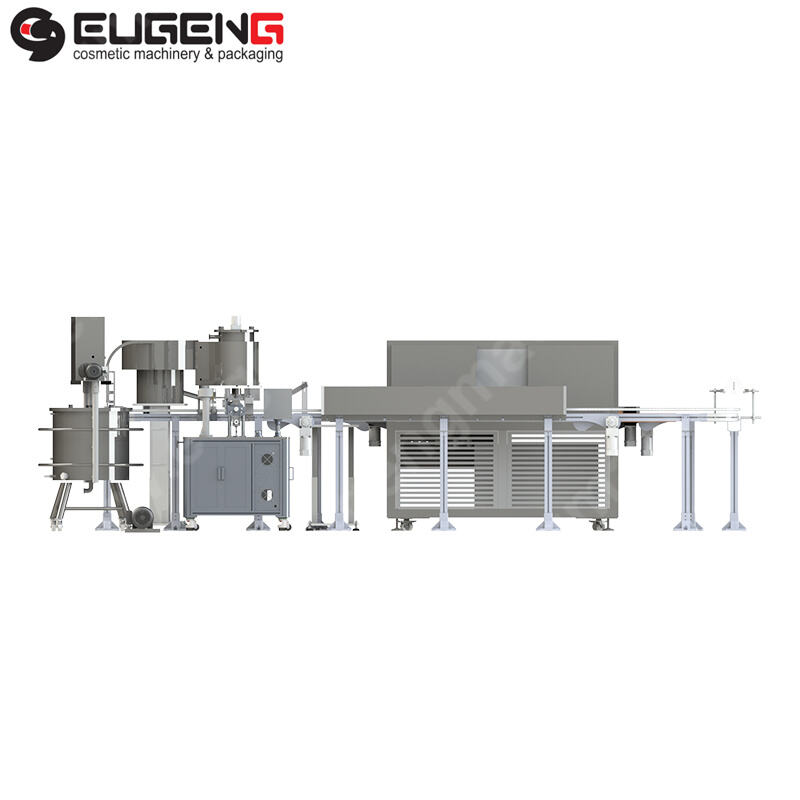

Nail polish filling machines can be integrated with other production systems including bottle feeding and capping systems, labeling and packaging equipment, data integration for traceability, and control. This kind of meticulous orchestration creates an assembly line that speeds up and standardizes your produce.

Upkeep and Troubleshooting

Best use of the nail polish fill machine requires common upkeep which includes habitual cleaning of the gadget, checking elements for put on and tear, and ensuring that all factors are operational. Proper maintenance schedules should be created, and issues should be fixed immediately to avoid any machine downtime.

Customization and Scalability

We offer nail polish filling machines that can be customized to meet manufacturing needs, various bottle shapes, and different volume options. Another important thing is scalability because manufacturers can be forced to require more production capacity due to increasing demand.

Bang for Your Buck and ROI

Nail polish filling machine comes with a high initial cost investment but if you see on a larger scale, its successful in many things from better efficiency, reduced waste to diminished labour requirement ultimately saves all those pennies after which this investment is paid off. Its payback period is short, but the long-term value it offers makes for an enticing proposition to manufacturers.

Regulatory Compliance and Quality Standards

Following regulations for cosmetic industry is extremely important to ensure safety and quality of nail polish products. Vernis à ongles filling machines should be certified and go through standards of manufactural quality to guarantee that the final product will not cause consumer harm.

Technical Approach to Nail Polish Filling in Future

On the whole, with every single day of industrialization and automation, obviously a nail Polish filling machine will not end at this level; as there is always room for improvement. A wide variety of tie ups with smart factory technologies and environmental innovations will propel them, pushing for efficiencies, embedding sustainability within every part of the business unit.

Conclusion

The nail polish filling machines are an amazing automation solution for nail polish manufacturers looking to automate and optimize its productions. High quality filling machine can meet the growing demand for a nail polish.

EN

EN

AR

AR BG

BG HR

HR CS

CS DA

DA NL

NL FI

FI FR

FR DE

DE EL

EL HI

HI IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RO

RO RU

RU ES

ES SV

SV TL

TL IW

IW ID

ID LV

LV LT

LT SR

SR UK

UK VI

VI HU

HU TH

TH TR

TR FA

FA MS

MS UR

UR BN

BN LO

LO LA

LA PA

PA