How the eyeshadow press machine play role?

Introduction

Eyeshadow is one of the cornerstones of the cosmetics industry, providing a multi-faceted array of color and finish that allows unlimited creativity and self-expression. With the increasing demand for high-quality and consistent creative products, along with the need to produce novel textures and colors eyeshadow must surely be a duty placed on technology today. One such technology is the eyeshadow press machine - this plays a leading role in the production process. This article will introduce in detail how the eyeshadow press machine machinery works and why it benefits the cosmetics industry.

Working Principle of the Eyeshadow Press Machine

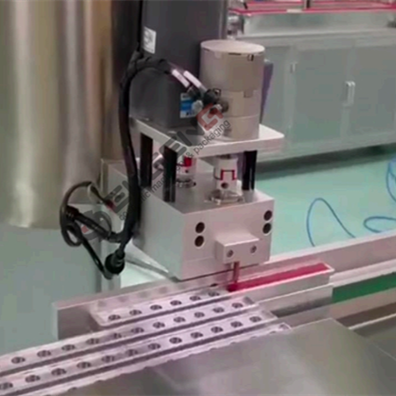

The eyeshadow press machine is a specialized piece of equipment that compacts powder types into eyeshadow form. Through precisely controlled pressure, it ensures uniformity and consistency in every single product. The machine consists of several major parts: a press mechanism to provide power and control, a die set for extrusion shaping the eyeshadow, and a control system regulating this overall process.

Various kinds of eyeshadow press machines exist. For example, there are single action presses and double action ones; fully automated press lines which interlock with other production equipment further upstream in manufacture etc.

The Role of the Eyeshadow Press Machine in Production

The eyeshadow press machine alone can fulfill these functions in the entire production chain:

A. Pressing Powders into Desired Shapes and Sizes: Shape the eyeshadow into the desired shape, be it a compact, pan or single, so that it can be luxuriously enjoyed by design for use.

B. Ensuring Unvarying Quality and Consistency: The press machine assures that all eyeshadow is of uniform density and quality by giving it optimal pressure, creating a natural message of its own with every product for consumers to identify.

C. Raising Efficiency and Reducing Labor Intensity: Automation through the press machine reduces the intensity and need for manual labor, hence increasing their production efficiency and eliminating potential human error.

Benefits of an Eye Shadow Press Machine Using

An eyeshadow press machine has a number of benefits:

A. Enhanced Product Consistency and Aesthetic Appeal: Pressed powders offer a uniform appearance and texture which impressed customers as well makes for predictable application.

B. Improved Production Speed and Volume: there is the possibility of faster production from the machine than with manual methods, enabling operators to meet demand.

C. Reduced Material Wastage and Cost Savings: Accurate pressing reduces the amount of powder lost in production, for the benefit of both that accounts department performance scale as well as our environment footprint in general.

D. Flexibility in Product Design and Tailoring: Press machines can use different build molds, enabling you to produce eyeshadow in a broad range of shapes and sizes according both demand segments (to be that boy, girl or not) and present fashion trends.

Problems and Thoughts on the Topic

But even though there are advantages, making things can be challenging:

A. Initial Investment and Running Costs: For some manufacturers, the cost of beginning to use one of these machines may be very high.

B. Maintenance and Technical Support: These machines require regular maintenance and may sometimes need professional technical support, so this is another considerable running cost.

C. Training of Operators and Staff: Proper training must be provided in the use and operation of these machines to ensure that they are used effectively and safely.

D. Change in Trend and Market: Manufacturers have to consider how they can adapt to changes in the fashion or trend. They must provide their press machines with designs that are capable of flexibility.

Fusion with Other Production Systems

An eyeshadow press machine can be linked to other production systems to provide a full manufacturing process:

A. Linking with Mixing and Grinding Equipment: The machines can be wired into the equipment which mixes or grinds all of these various powders, helping to bring about a smooth transfer in every way from production to pressing.

B. Compatibility with Dust-off and Bagmaking Machines: The machines are made to interface with packaging and cutting machinery, forming one continuous production line for looping from pressing right through to final packaging.

C. Automation and Robotics Integration for Complete Production Lines: Advanced machines can become a part of an automatic production line which includes robotics for further efficiency and precision.

Impact on the Cosmetics Industry

More than anyone else, the eyeshadow press machine affects the manufacture of eyeshadow. What does it do to fruits of its own labor?

A. Meeting High Consumer Demand for Variety and Quality: Employing such a machine allows manufacturers to make many different and high quality eyeshadows to meet the diverse consumer demand.

B. Supporting the Growth of Small and Large Cosmetic Brands: Both small artisans and large manufacturers. Can benefit from press machines help to increase production efficiency as well as the purity of product.

C. Driving Innovation in Eyeshadow Product Development: This technology encourages manufacturers to play with different kinds of shapes. Now they're trying out new sizes and forms for the eyeshadow's design, driving innovation in this nonesuch.maske

Case Studies: Successful Implementations

A number of cosmetics businesses have successfully implemented eyeshadow press machines, bringing employees back on the line and raising product quality. Large manufacturers have been able to carry on with high production. Volume, while small You're Meeting manufacturers find they need cater mainly now to the consumers using their machines.

Future Trends and Technological Advancements

Eco-friendly pressing solutions are emerging in technology trends and advancing in pressing technology for precision, future eyeshadow press machines. Also IoT integration with data analytics creates smart manufacturing. There is a strong emphasis now too on developing eco-friendly pressing solutions to minimize the environmental impact of production.

Selecting the Right Eyeshadow Press Machine

Selecting the right eyeshadow press machine entails evaluation of production needs and capacity, conducting both a budget and cost-benefit analysis for it; looking into machine specifications and considering weight in the decision whether or not to buy at all. manufacturer s reputation after"

sales support image and service

Conclusion

In summary, the eyeshadow press machine has a significant impact on the cosmetics industry. By guaranteeing product quality, consistency and production efficiency, this technology plays a vital role in ensuring high manufacturing yield, very little scrap (manufacture so far behind schedule that money starts to prove unprofitable or takes away form other sources )As the is trend towards Information Mediums does not come to an end producers need out learn more about such requires. Some such technologies will be essential to employers who are looking for the use of technology in their operations. What then?

EN

EN

AR

AR BG

BG HR

HR CS

CS DA

DA NL

NL FI

FI FR

FR DE

DE EL

EL HI

HI IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RO

RO RU

RU ES

ES SV

SV TL

TL IW

IW ID

ID LV

LV LT

LT SR

SR UK

UK VI

VI HU

HU TH

TH TR

TR FA

FA MS

MS UR

UR BN

BN LO

LO LA

LA PA

PA