Model EGBM-80 cosmetic product cartoning machine is a automatic cartoning machine, widely used for the boxing of cosmetic products and related industries packaging. It can not only meet the production of a single variety in large quantities, but also meet the production of small batches of multiple varieties.

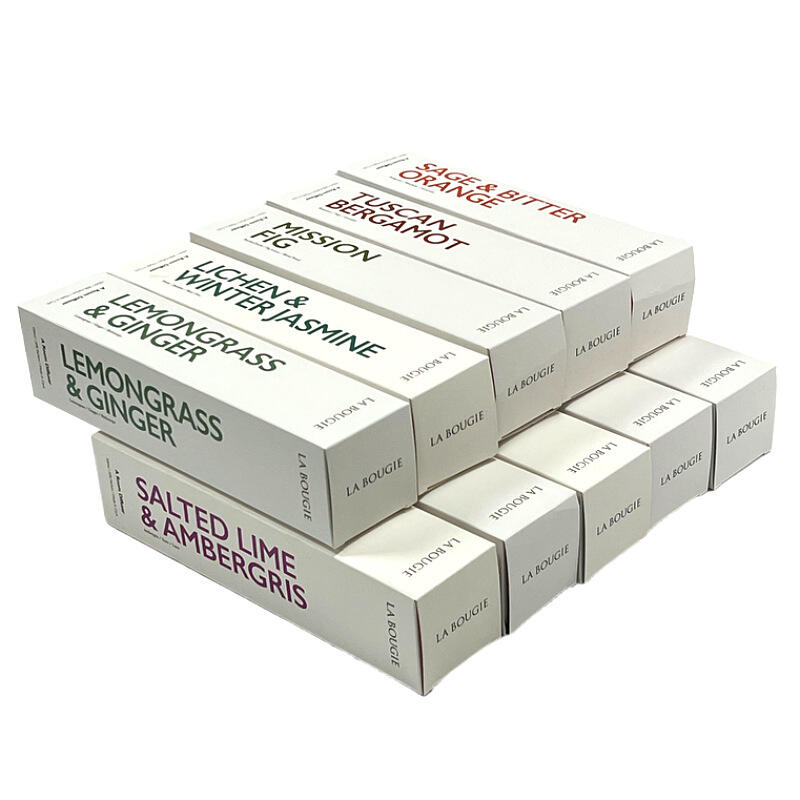

1.Target Products

|

|

|

|

2.Descriptions

3.Specifications and Parameters

| Model No. | EGBM-80 |

| Production type | Horizontal type |

| Output capacity/hr | 80boxes/min |

| Applicable size range | L(70-230)mm×W(25-80)mm×H(15-50)mm |

Conveyor control Type |

Air control |

Display |

PLC |

| No. of operator | 1 |

| Powder consumption | 0.75kw |

| Dimension(M) | L2.8×W1.05×H1.7 |

| Weight | 500kgs |

Air pressure |

0.5~0.7Mpa |

Air consumption |

≥150L/min(ANR) |

Breakage rate |

3‰ |

4.Details

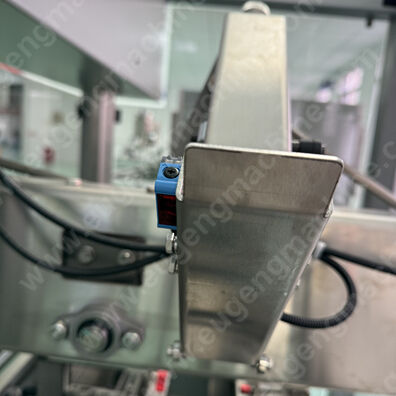

|

|

|

|

| PLC control | Conveyor holder | Sensor check, no product no boxing | Vacuum picking paper box |

5.Reference Video