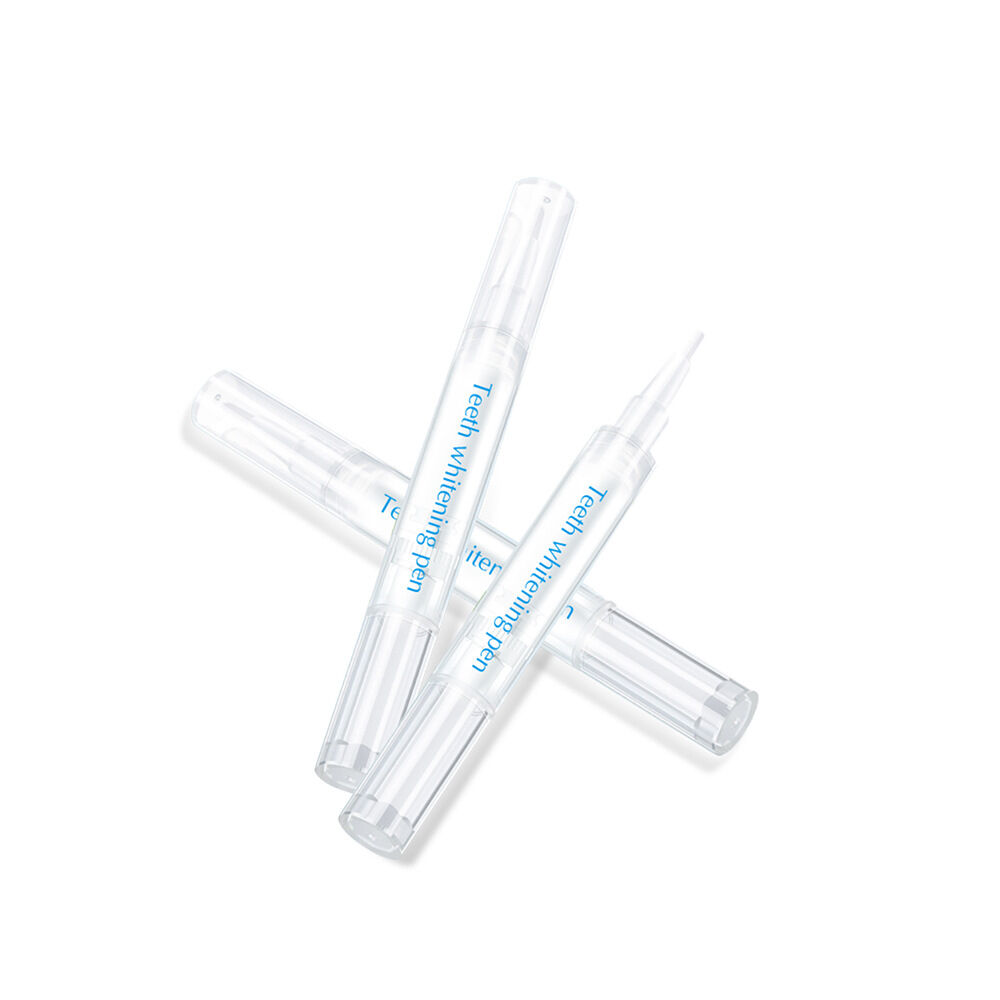

Model EGMF-02 is a push type semi automatic piston filling and capping machine, designed for the production of lip gloss, liquid lipstick, mascara, eyeliner, nail polish, cosmetic liquid foundation, concealer, essential oil, lotions, serums, cream, perfume card, teeth whitening pen etc.. It has automatic filling and capping functions, suitable for round, square and irregular shape bottles. Can fill both water base liquid and high viscosity gel/ paste liquid.

1.Target Products

|

|

|

|

2.Descriptions

3.Specifications and Parameters

| Model No. | EGMF-02 |

| Output capacity | 35-37pcs/ min |

| Filling volume | 0-50ml |

| No. of nozzle | 1 |

| No. of holder | 65 |

| Tank volume | 30L/ set |

| Powder consumption | 2.5kw |

| Air put | 4-6kgf |

| Dimension(M) | 1.5×0.8×1.9 |

| Weight | 450kgs |

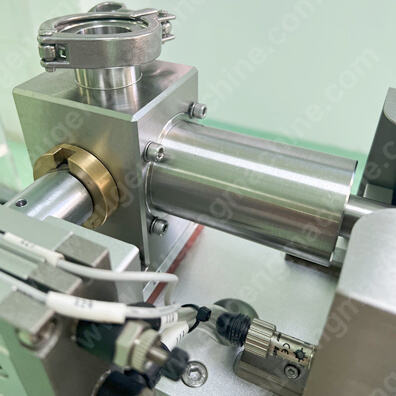

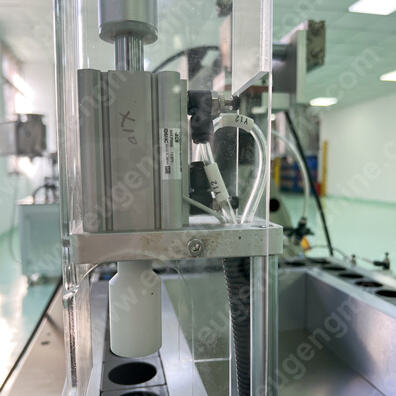

4.Details

|

|

|

|

| Push table with 49 puck holders | Sensor checking, no tube no filling | Filling nozzle with guider, prevent broken | 30L pressure tank |

|

|

|

|

| Piston filling, driven by servo motor | Pressing wiper by air cylinder | Adjust capping height ad as tube size | Automatic discharge by air cylinder |

5.Reference Video