Hot filling line widely used in cosmetics

I. Background Information

Product quality and safety are the most important factors in cosmetics. And the industry is always anxious to seek any new techniques that can contribute towards preservation of these values. In contrast, this hot filling line, appear in 1980 s at first only as an idea born in life insurance policy meetings. It seems that this spur-of-the-moment invention will now become deeply rooted in our daily work and life-the natural outcome of "everyone washing their own pants" to enlarge world common cosmetology knowledge.

II. Definition of Hot Filling Lines

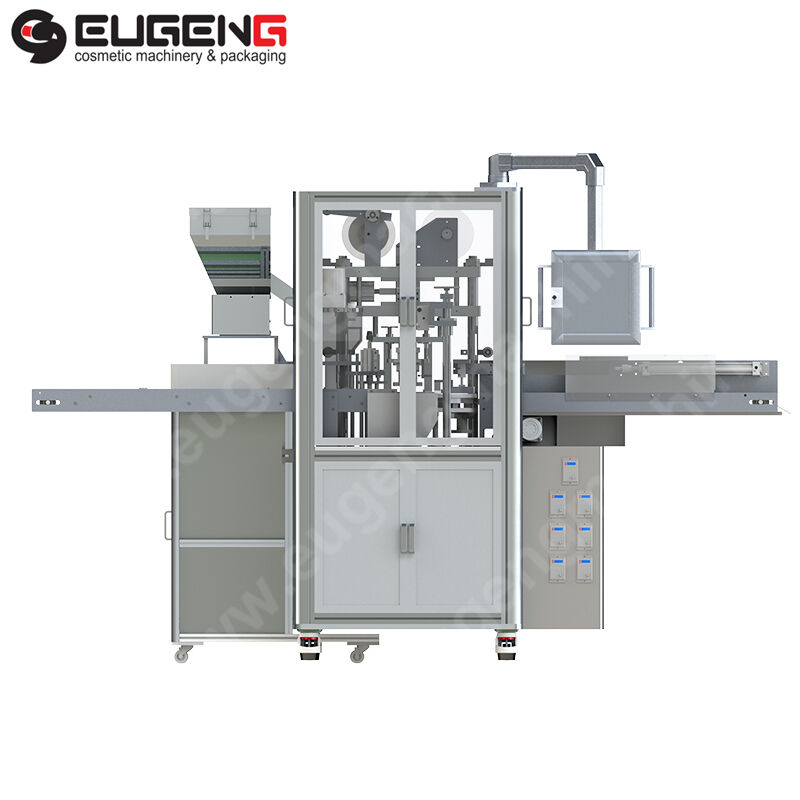

A hot filling line is a process that involves filling product directly into container as it cools them, then immediately sealing. It is particularly useful for products which are sensitive to bacterial contamination or contain heat-labile ingredients. Usually the turnover consists of a filler, a body machine and a cooler tunnel.

III. Why Hot Filling is Crucial to Cosmetics

There are several reasons why hot filling is necessary for cosmetics. It can help keep active ingredients intact because than most the ones that were present have been destroyed and with preservatives it has extended products' shelf life. Consuming customers also find this process convenient since when the original product appears unopened again for use, they think of after all that is an entirely fresh package.

IV. The Hot Filling Process in Cosmetics

The hot filling process begins before a preliminary stage on the production lines, after preparation; the raw material must be enough hot to fill. The hot product is then poured into containers with the aid of special, nozzled filling machines; these are immediately sealed, so as to trap the heat inside and kill off any surplus microorganisms. After filling, the product is cooled to do mode for room temperature so that it will solidify and can be conveniently packed without collapsing on itself.

V. Benefits of Hot Filling Lines for Cosmetics Production

Hot filling lines can provide a host of advantages, including enhanced product safety due to microbial contaminants being lowered. Long-term, they also offer income-producing solutions in the form of fewer preservatives and longer product shelf lives. In addition, these lines boost production efficiency while offering flexibility on how to package your goods varied market attributes are catered for in this way.

VI. Challenges and Considerations

Despite the advantages, there are obstacles connected with hot filling production lines The initial investment and setup costs can be daunting, and continuing maintenance and operational costs should not be overlooked. Energy consumption is another factor involved with the heating process that hot filling requires for it to work properly. Lastly, staff members need to be trained in order for the line to run safely and efficiently.

VII. Integration with Other Production Systems

Hot filling lines can be integrated with other manufacturing systems to form a seamless production process. This includes linking up with filling and capping machines, automation and robotics applications, as well as compatibility to labeling and packing equipment. Data tracking and traceability systems can also be integrated, to guarantee the quality and safety of the products manufactured.

VIII. Case Studies: Successful Implementations in the Cosmetics Industry

Hot filling lines have been successfully implemented across various areas of the cosmetics sector Large-scale operators use them to keep production volumes high, whilst for SMEs they prove invaluable in realizing their niche products. In addition, based on their dedication to natural and preservative-free merchandise, organic cosmetics brands have in recent years begun to see the advantages of using hot filling methods for product supports.

IX. Future Trends and Technological Advances

Integrating Internet of Things technology will lead to many changes in the future configuration of smart filling lines, though it is still in early days. The combination of energy-saving technologies and hot-filling looks bright for the future. more customizable options will give better production flexibility There is now increasing significance on sustainable development practices. This means finding ways that provide less waste and save energy.

X. Selecting the Right Hot Filling Line for Your Cosmetics Venture

When selecting the correct hot filling line, a number of considerations must be made, including production needs, a budget and cost analysis, machine specifications and scalability for future growth. Manufacturers and vendors should have ample experience to help you grasp the proper logic of choosing a suitable line at this point in time for your business.

XI. Conclusion

In conclusion, hot filling lines are their very one to the cosmetics industry: they guarantee product quality and safety. There are many benefits to be obtained from using these systems--including raw material preservation for a longer shelf life, and better consumer appreciation of products. Despite the many challenges confronted, the introduction of hot-filling technology can greatly affect cosmetic business success.

EN

EN

AR

AR BG

BG HR

HR CS

CS DA

DA NL

NL FI

FI FR

FR DE

DE EL

EL HI

HI IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RO

RO RU

RU ES

ES SV

SV TL

TL IW

IW ID

ID LV

LV LT

LT SR

SR UK

UK VI

VI HU

HU TH

TH TR

TR FA

FA MS

MS UR

UR BN

BN LO

LO LA

LA PA

PA