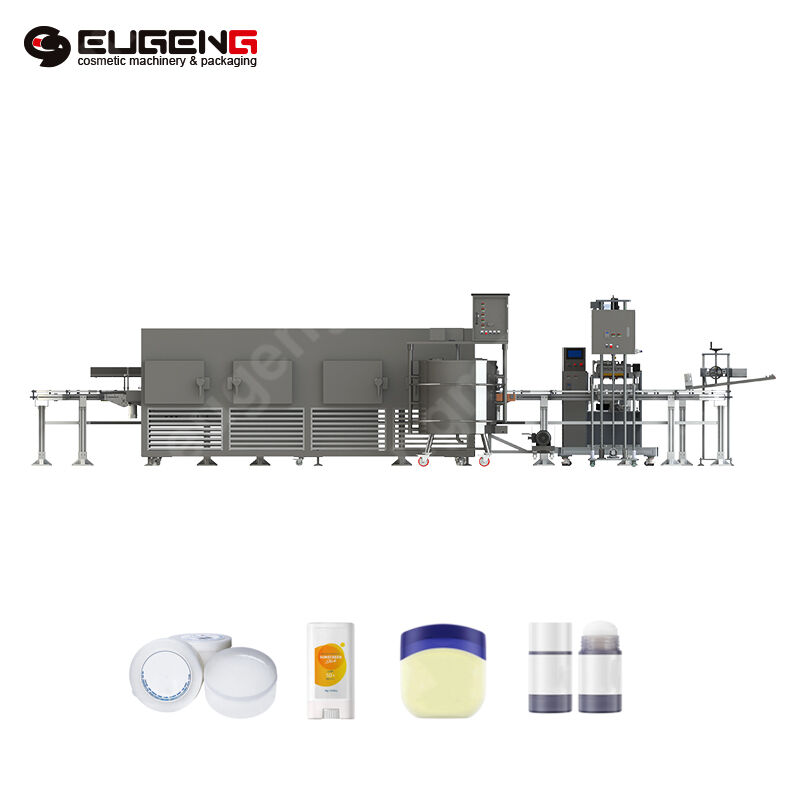

This is an automated industrial equipment specifically designed for the production of personal care products - deodorant sticks. It is mainly used to precisely, hygienically and efficiently fill liquid or semi-solid pastes, gels or wax-based formulations into specific rotating containers.

I. Main Components and Working Principle of the Deodorizer Stick Filling Machine

A typical odor-removal stick filling machine usually consists of the following core components:

Filling System:

◦ Storage tank/dump tank: Used to store the deodorant raw material that has been heated and turned into a liquid state. It usually has an insulation jacket and a temperature control system to maintain the material in a suitable flowing condition.

◦ Metering pump: This is the core component of the filling machine. Usually, a piston pump is used. Through precise stroke control, it ensures that each product is filled with exactly the same volume, with extremely high accuracy.

◦ Filling head/nozzle: This component injects the material pumped by the pump into the container. Its design must ensure no leakage or dripping, and no stringing. It also needs to guarantee the cleanliness of the container opening.

2. Container Processing System:

◦ Conveying mechanism: Usually, a loop-type conveyor belt is used to orderly transport the empty containers (including the bottle body and base) to each workstation.

◦ Positioning and clamping mechanism: At the filling station, the mechanical hand or fixture will accurately grasp and secure the container, ensuring that the filling nozzle can align with the bottle mouth and preventing spillage.

3. Control System:

◦ PLC (Programmable Logic Controller): The brain of the equipment, controlling the operation rhythm, filling volume, temperature and all other parameters of the entire machine.

◦ Human-machine interface (HMI touch screen): Operators use the screen to set recipe parameters (such as filling volume and temperature), monitor production status, and view production output and fault information.

◦ Sensors: Distributed throughout the machine, they are used to detect the position of the container, the level of the material, whether the temperature is normal, etc., to ensure the safety and reliability of the process.

4. Cooling or curing system:

After being filled, the deodorizing sticks are usually in a liquid or semi-solid state, and they need to be quickly cooled and shaped to prevent deformation.

The common method is that after filling, the product passes through a cooling tunnel where it is rapidly and evenly solidified by cold air. This is a key feature that distinguishes this machine from other liquid filling machines.

Basic workflow:

Empty bottle loading → Positioning at the filling station → Filling head descends and injects the measured material → Cooling → Cap/Sealing → Finished product output.

II. Key Features and Technical Requirements of the Deodorizer Stick Filling Machine

High-precision filling: The deodorant sticks are personal items that come into direct contact with the skin. The volume must be consistent; otherwise, it will affect the user experience and brand image. The accuracy is usually within ±0.5%.

2. Temperature Control: The majority of deodorant stick formulations require heating and melting before being filled. Therefore, the entire material path from the hopper to the filling head must have a precise heating and insulation system, with high temperature control accuracy requirements (typically ±1°C).

3. Anti-sticking and anti-tearing: The raw materials of the deodorizer are usually quite viscous. The filling head must have a special design (such as a back-suction function) to cut off the material flow at the end of filling, preventing the material from sticking to the bottle mouth and affecting the appearance and subsequent packaging.

4. Flexibility: A good filling machine should be capable of accommodating containers of various sizes (with different diameters and heights) and formulations of different viscosities. The replacement of molds and adjustment of parameters should be relatively straightforward.

5. Hygiene Design: The parts in contact with the materials should be made of materials such as 316 stainless steel, which are easy to clean and resistant to corrosion, and comply with GMP (Good Manufacturing Practice) requirements.

6. High degree of automation: Modern filling machines can automatically complete all steps such as bottle insertion, filling, cooling, cap placement, screwing, and discharging. Only 1-2 operators are needed for monitoring.

III. Factors to Consider When Selecting Deodorizer Stick Filling Machines

If you need to purchase such equipment, you should pay attention to the following points:

• Production speed: What production capacity is required (e.g., pieces per hour)? This determines the size and cost of the equipment.

• Container specifications: What are the diameter, height and shape of the bottle you are using? The equipment supplier needs to provide corresponding fixtures and molds based on this information.

• Material characteristics: What type of base is your formula (wax-based, gel-based, alcohol-based)? What are the viscosity, melting point, and curing temperature? These factors directly influence the selection of the equipment's temperature control system and pump type.

• Automation requirements: Do we need the functions of automatic bottle loading and automatic cap placement? Or a semi-automatic system will suffice?

• Budget: Fully automatic high-speed production lines are expensive, while semi-automatic equipment is much more economical. One needs to consider the initial investment and the long-term labor costs.

In summary, the deodorant stick filling machine is a highly specialized equipment that integrates mechanical, temperature control, and automation technologies. It is the core component in the production of deodorant sticks, and its performance directly affects the quality, appearance, and production efficiency of the products.

EN

EN

AR

AR BG

BG HR

HR CS

CS DA

DA NL

NL FI

FI FR

FR DE

DE EL

EL HI

HI IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RO

RO RU

RU ES

ES SV

SV TL

TL IW

IW ID

ID LV

LV LT

LT SR

SR UK

UK VI

VI HU

HU TH

TH TR

TR FA

FA MS

MS UR

UR BN

BN LO

LO LA

LA PA

PA