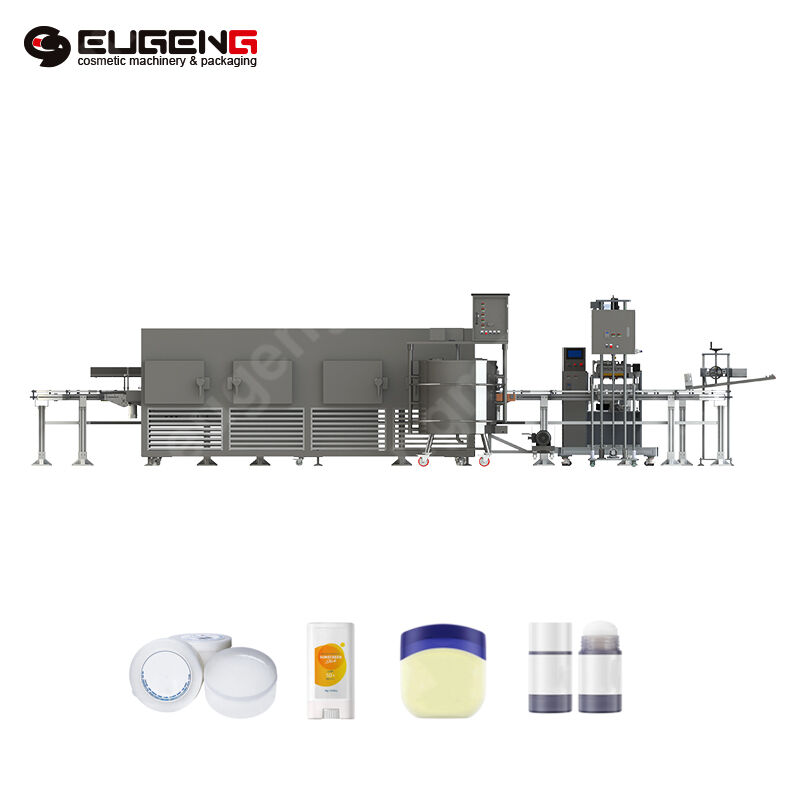

Acesta este un echipament industrial automat, conceput în mod specific pentru producția de produse de îngrijire personală - stickuri antiperspirante. Este utilizat în principal pentru a umple în mod precis, igienic și eficient lichide sau paste semisolide, geluri sau formule pe bază de ceară...

VEZI MAI MULT

Îmbunătățirea randamentului și a consistenței în fabricarea de ruj În lumea în continuă evoluție a cosmeticii, cererea pentru produse și așteptările clienților cresc constant. Pe măsură ce brandurile se străduiesc să ofere rujuri de înaltă calitate și cu aspect atrăgător estetic în cantități mari...

VEZI MAI MULT

Mastery-ul Preciziei în Producția de Ruj Industry cosmetică se bazează pe consistență, calitate și inovație. Printre cei mai importanți factori în fabricarea rujului se numără precizia procesului de umplere. Orice abatere în volum, textură sau ...

VEZI MAI MULT

Îmbunătățirea Eficienței Producției în Industria de Frumusețe Industria cosmetică se bazează pe precizie, consistență și viteză - mai ales atunci când este vorba de fabricarea produselor cu cerere ridicată, cum ar fi rujul. Cu așteptările consumatorilor în creștere și pro...

VEZI MAI MULT

Răspunderea Cererii Prin Automatizare Industria de frumusețe este martorul unei creșteri fără precedent în cerere, în special pentru cosmetice coloristice precum gloss-ul de buze. Pentru a rămâne competitivi și a satisface așteptările consumatorilor, producătorii de cosmetice apelează rapid la...

VEZI MAI MULT

Revolutionarea fabricației cosmetice prin automatizare În industria frumuseții, în continuă evoluție, inovația este esențială pentru a rămâne competitiv. Pe măsură ce cererea consumatorilor crește pentru produse cosmetice de înaltă calitate și produse în condiții de igienă, automatizarea a devenit un element vital ...

VEZI MAI MULT

Îmbunătățirea trasabilității produselor cu ajutorul mașinilor de etichetareUrmărirea în timp real prin RFID și coduri de bareTehnologiile de identificare prin frecvență radio (RFID) și de etichetare cu coduri de bare pot îmbunătăți semnificativ trasabilitatea produselor de-a lungul lanțului de aprovizionare. Astfel de sisteme pot urmări...

VEZI MAI MULT

Avantajele operaționale ale soluțiilor automate de etichetareReducerea erorilor umane în medii cu viteză mareMașinile automate de etichetare elimină practic eroarea umană și sunt capabile de operare la viteză mare. În astfel de condiții, sistemele sunt esențiale...

VEZI MAI MULT

Bazele automatizării dozării cosmeticeCum funcționează automatizarea dozării cosmeticeAutomatizarea dozării produselor cosmeticeFolosind tehnologie avansată pentru a umple produse cosmetice în diverse recipiente. Această operație este din fericire nu doar o statică...

VEZI MAI MULT

Tipuri de mașini de dozare cosmeticăDozatoare cu pompă pentru lichide și loțiuniDozatoarele cu pompă sunt necesare și pentru a manipula lichide ușoare care curg liber, cum ar fi loțiunile și parfumurile în industria cosmetică. Aceste dozatoare garantează o umplere uniformă și...

VEZI MAI MULT

Evoluția tehnologiei de umplere cosmetică: De la sisteme manuale la sisteme automate. În zilele prime ale industriei cosmestice, metodele manuale de umplere erau norma, ceea ce aducea deseori variabilitate în calitatea produselor și timpuri mai lungi de producție. Tradițional...

VEZI MAI MULT

Îmbunătățirea Eficienței de Producție cu Sisteme Automate Automatizarea îmbunătățește semnificativ eficiența de producție prin accelerarea vitezelor liniei de ambalare cu ajutorul tehnologiei. Sistemele automate, prin reducerea intervențiilor manuale, pot crește remarcat ambalarea...

VEZI MAI MULT